Battery Drop Test Machine 丨Battery Drop Impact Test Machine丨Battery Free Drop Tester

- Model

- HUD-H202

Item specifics

- The weight of the test piece

- 2kg±100g

- Drop height

- 400~1500mm (adjustable)

- Control method

- metal button control

- Lifting method

- automatic lifting

- Falling method

- free fall

- Drop surface size

- 560x410x10mm

Review

Description

Application

BATTERY DROP TEST MACHINE is suitable for the free fall test of small consumer electronic products and parts such as mobile phones (mobile phones), walkie-talkies, electronic dictionaries, intercom phones in building apartments, CD/MD/MP3, etc.; the machine adopts pneumatic structure and will be tested. Place it in a special fixture (adjustable stroke) to clamp firmly, press the drop button, the cylinder is released, the specimen will be tested in a free fall, the height of the drop can be adjusted up and down, the altimeter can know the drop height of the specimen, the key components of this machine Reliable performance, a variety of drop floors are available.

Standards

GB/T 31241-2014 "Safety requirements for lithium-ion batteries and battery packs for portable electronic products"

UN38.3 "United Nations Manual of Transport Tests and Standards for Dangerous Goods"

IEC62133 "Battery (group) composed of batteries and safety requirements for portable equipment"

UL 1642:2012 "Lithium Battery Standard"

Main Parameters

1. The weight of the test piece | 2kg±100g; |

2. Drop height | 400~1500mm (adjustable); |

3. Control method | metal button control; |

4. Lifting method | automatic lifting; |

5. Falling method | free fall; |

6. Height accuracy | ±1mm; |

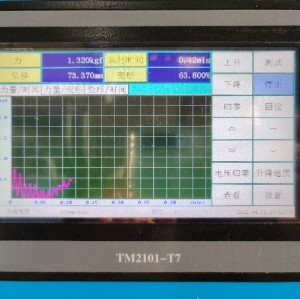

7. Height display | LED screen display; |

8. Clamping method | pneumatic clamp; |

9. Material of drop board | steel plate; |

10. Air source | ≥0.4MPa; |

11. Drop surface size | 560x410x10mm (width x depth x height); |

12. Dimensions | 570x650x1730mm (width x depth x height); |

13. Weight | 80kg |

14. Power source: | 1∮, 220V, 3A |