Battery Explosion-Proof Testing Machine丨Dual Anti-Explosion Test Chamber

- Model

- HUD-H203

Item specifics

- Inner box size

- 500x500x500mm

- Dimension

- 680x750x1475mm

- External material

- cold-rolled steel plate with paint treatment, thic

- Internal materia

- SUS#304 thickness 1.2mm

- Number of cabinets

- 2

- Control mode

- metal button control

Review

Description

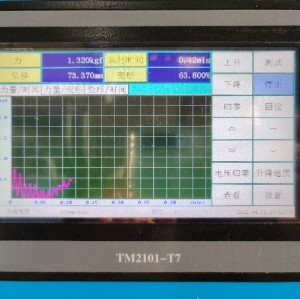

Battery Explosion-proof Testing Chamber is mainly used for charging and discharging of battery.Put the battery in explosion-proof chamber and connect charge and discharge tester to protect the operator and equipment. The body is made of steel material with strong texture and well explosion protection.

Test Standard

- UN38.3(2012) "Recommendations on the Transport of Dangerous Goods-Manual of Tests and Standards" Part III

- IEC62133-2012 "Safety requirements for batteries and battery packs containing alkaline or non-acid electrolytes"

- GB/T 31485-2015 "Safety requirements and test methods for power batteries for electric vehicles"

- GB31241-2014 "Safety requirements for lithium-ion batteries and battery packs for portable electronic products"

1. Inner chamber size | 500x500x500mm (width x depth x height); |

2. Dimensions | 680x750x1475mm (width x depth x height, including door lock); |

cold-rolled steel plate with paint treatment, thickness 1.5mm; | |

4. Internal material | SUS#304 thickness 1.2mm; |

2; | |

6. Box door | a single door opens to the left, and an explosion-proof chain is installed on the side of the box door; |

7. Teflon tape is attached to the inside of the box, which is effective in insulation and flame retardant, easy to clean; | |

8. There are test holes on the left side of each layer of the box, which is convenient for the test connection line to pass through; | |

9. Each test box has a lighting and smoke exhaust interface, and there is an interval design between each layer to avoid mutual influence on the test; | |

10. Control mode | metal button control ; |

11. Pressure relief door size | 200x200mm; Located at the back of the box, when the sample explodes, the pressure relief port will pop open to relieve the pressure; |

12. Smoke exhaust pipe | diameter φ100mm, located at the back of the box; |

13. Observation window | Two-layer tempered glass with a size of 250x250mm, equipped with stainless steel mesh; |

14. Equipment movement | There are four universal casters at the bottom of the equipment, which can move freely; |

15. Lighting device | It is convenient to observe the state of the tested sample; |

16. Power supply | 1∮; AC220V; 50-60HZ |

Observation Window

Easy to observe the condition of the sample at any time

Inner Chamber

SUS#304 thickness 1.2mm

Double Handle

Silicone compression strip + explosion-proof chain handle

Separate Exhaust & Lighting System