Maintenance Of UV Aging Test Chamber

- Share

- publisher

- Lisa Zhong

- Issue Time

- Jul 15,2014

Summary

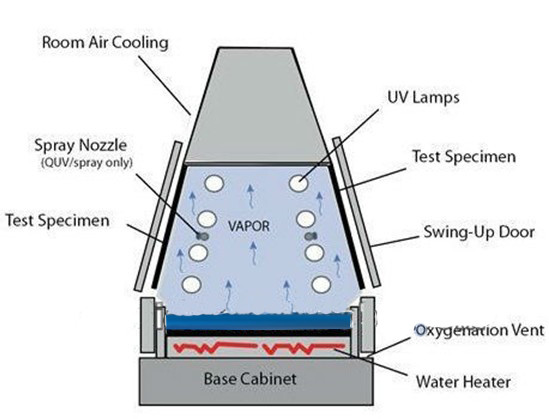

UV aging test chamber using ultraviolet light to simulate the sun, but also by condensation or spray the way to simulate the impact of moisture. The equipment is tested by exposing the material to be tested in an alternating cycle of controlled sunlight and moisture while increasing the temperature. The production of UV aging test box using CNC machine tool processing, handsome in appearance, and the use of two-way clamshell, easy to operate.

UV aging test chamber using ultraviolet light to simulate the sun, but also by condensation or spray the way to simulate the impact of moisture. The equipment is tested by exposing the material to be tested in an alternating cycle of controlled sunlight and moisture while increasing the temperature. The production of UV aging test box using CNC machine tool processing, handsome in appearance, and the use of two-way clamshell, easy to operate.

Factors affecting the UV aging test chamber:

1. Inside temperature:

During the irradiation or stop phase, the test procedure specified in the temperature of the tank shall be controlled and the relevant specification shall be in accordance with the intended use of the equipment or components.

2. Airflow speed:

The size of the airflow velocity close to the surface of the sample, in addition to the temperature rise of the sample, also makes significant errors in the open thermostat of the monitored radiation intensity.

3. Surface contamination:

Dust and other surface contaminants will severely alter the absorption properties of the surface of the subject, ensuring that the sample is clean.

4. Humidity:

Various materials, coatings and other substances in different humidity conditions, the difference between the photochemical deterioration of the larger, the requirements of the humidity conditions are not the same, the specific humidity conditions specified by the relevant norms.

Maintenance of UV aging test chamber

1. Keep the appearance of the box clean; to avoid dust intrusion into the box; to avoid external impact of the box;

2. prohibit the chemical contact with the equipment; laboratory to maintain a dry environment; absolutely prohibit the set temperature exceeds the maximum temperature specified by the device;

3. Check the circuit control system before each boot; the confirmation of the power supply and ground wire;

4. whether the power cord in accordance with the specifications properly connected, and indeed grounded;

5, check the over-temperature protection, has been set up (the factory has been adjusted, generally do not need to adjust);

6. Laboratory should be installed ventilation fans, to maintain indoor ventilation;

7. Spray test should pay attention to observe the water level of the tank, timely replenishment of pure water;

8. The wastewater discharge system of the equipment must be installed in place; after the end of the test, the whole power supply should be cut off;

9, after the end of each test, the sample should be removed, clean the equipment liner clean;

10. Do not operate the equipment for non-professionals.

11. During the operation of the equipment, be sure to maintain adequate water;

12. The test phase should minimize the time to open the door;

13. Non-full-time operators shall not operate at will;

14. Please contact Aisi Lai Instrument Co., Ltd. when you can not troubleshoot your equipment.

15. After prolonged use for a long time, if you need to re-use, you must carefully check the water, power and components, and then correct the device.

If you have any question ,contact us please !

Contact:Lisa Zhong

Phone: +86-7698-1187866,+86-13829267288.

Email: manager@climatetester.com.

Website:http://www.climatetester.com/