The Grade Of Resistant To Yellowing

- Share

- publisher

- Lisa Zhong

- Issue Time

- Sep 20,2010

Summary

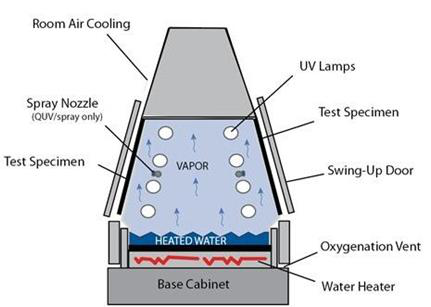

Anti-yellowing aging test chamber for the simulation of the sun's ultraviolet radiation and heat, the sample in the machine by the role of ultraviolet radiation and temperature, after a period of time, observe the degree of yellowing resistance of the sample can be used as a reference gray stained gray, Determine the level of its yellowing.

1, yellowing:

In the natural sunlight, ultraviolet light for a long time or in the heat, oxygen, stress, trace moisture, impurities, improper process under the action of the phenomenon of yellow color, called yellow.

In general there are three reasons for the yellowing

1, high temperature

2, long-term light, weathering (weatherability)

3, the reaction occurred

But the specific resistance to yellowing the standard will be different because of the application of different directions.

For one

High temperature, some plastic requirements do not yellowing at 300 ℃, then there is no yellowing at 180 ℃ like;

For two

Weatherability, the general test to be carried out when the 1000-1500

Hour, but the actual use of the request may be less than or greater than the length of time. ;

For three

Reaction to more understand, and some acid, and some alkali. While TPE

The resistance to yellowing is calculated according to the anti-UV intensity, and the best is the transparent grade. With ultraviolet light

Shoot, see the degree of yellow, contrast color card

2, TPU resistance to change the level of how to divide?

Generally compare the gray card, 1-5 points. After resistance to yellowing tests such as Sun test, QUV

Or other sun and other tests, the contrast test before and after the sample color change, the best level is 5, on behalf of the basic does not change color.

3, The following is clearly discolored.

In general, 4-5 level, is a little discoloration, it has to meet most of the TPU

The application of the. If you need to completely do not change color, generally need to use the aliphatic TPU, is the so-called non-yellowing TPU, substrate non-MDI, Usually HDI or H12MDI, etc., long time UV test will not change color.