What is a test chamber and how does it work?

- Share

- Issue Time

- Mar 6,2018

What is a test chamber and how does it work?

The importance and the operating principles of a test chamber

Have you ever bought a product that turned out to be defective after just a few weeks, or even the first time you used it?

This might have happened because some products have been subjected to external factors such as temperature, humidity and vibrations that were not expected or otherwise taken into account when they were being designed.

In today’s global market in which every product can be sold in the most remote corners of our planet, it is essential that the development and design phase takes into consideration the different environmental conditions to which the product will be subjected, from warmer to cooler climates, the effect of salt corrosion, and many other factors.

In addition to the usage conditions, it is good to take into account the various stresses that the product may be subject to during packaging, transport and storage operations, which could cause damage or shorten the useful life of the product.

So, what needs to be done to avoid these kinds of potential drawbacks and ensure greater product reliability?

The apparently simple answer would be to test the product in all its usage conditions, but this can be done if and only if you have a test chamber. Special temperature and humidity conditions can be recreated inside an environmental test chamber in order to verify a product’s reliability, durability or resistance to atmospheric agents.

Using an environmental test chamber helps you discover potential defects to be corrected before the production stage, ensuring:

Lower maintenance costs

Satisfied Customers

So, now that we know how important an environmental chamber is, let’s find out how it works.

It must be said that there is no universal chamber that can simulate any and every type of conditions, but there are many types of more or less versatile chambers that are designed to perform specific types of tests. For an overview of the main models please go to the article "The test chamber". In this case we will look at the family of chambers most commonly used: the climatic chamber.

A climatic chamber is a machine designed and built to simulate certain temperature and humidity conditions inside a test compartment.

HOW DOES IT WORK?

The operating principle of a test chamber can be explained by the two phisical parameters that the chamber can control: temperature and humidity.

TEMPERATURE CONTROL

In order to control the temperature, the chamber must be able to perform two functions: heating and cooling. It also must be able to evenly distribute the temperature inside the test compartment.

Specific technical considerations about the distribution of air within the test compartment make it possible to achieve great uniformity of the temperature values over time and throughout the space of the chamber, ensuring that all parts and surfaces of the DUT are subjected to the same temperature.

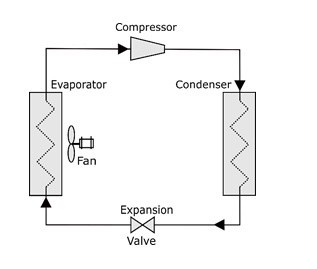

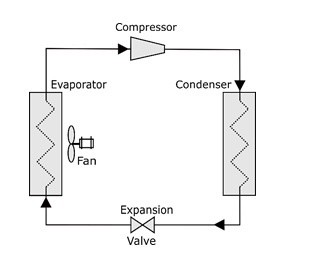

The mechanical cooling system of a climatic chamber consists of a closed circuit system, with the following main components:

compressor

condenser

expansion valve

evaporator

By means of the compression and subsequent expansion of a refrigerant gas, the process will uniformly cool the test compartment.

There are two minimum temperature values according to which climatic chambers are commonly classified: single stage, those with a minimum temperature of -40°C, and

double-stage (i.e. with a cascade system), with a minimum temperature of at least -70°C.

The mechanical heating system consists of electric heating elements placed near the ventilation system: the heated air is conveyed by means of ventilation through the inside of the test compartment.

The action of the two functions of cooling and heating is controlled by the PLC according to the cycle parameters set by the operator to ensure the required performance.

HUMIDITY CONTROL

In order to control the humidity, the chamber must be able to perform two functions: humidification and dehumidification. It also must be able to distribute humidity uniformly within the test compartment.

Direct humidification is achieved by means of an electric humidifier, which injects steam through a hole in the air flow after the air recirculation fan. This ensures aerosol-free humidification. The humidifier is controlled by a dedicated algorithm for better reliability.

The chamber is dehumidified by a mechanical system based on the so-called cold finger principle, utilizing the same mechanical system used for cooling. According to this principle, when an object with a lower temperature is exposed to a higher ambient temperature, the moisture in the air condenses on the surface of the colder object. The evaporator is the element with the lowest temperature inside the climatic chamber, and a dedicated section of this is thus used to lower the humidity levels in the test compartment when required.